1861-1888: the "original idea"

The original founder and promoter of our Company was Luigi Zamboni, born in Bologna into a family of humble origins on May 21, 1861, at the time when Italy was unified.

At the age of about 30 years old - we were by the end of the century - he began to think of "a machine to make tortellini".

Zamboni had become an expert in mechanics by working as a qualified turner at the "Pyrotechnic Unit", the Military Arsenal in Bologna between Azeglio's and Castiglione's Gate. The Arsenal was an important bullet factory, as well as a "school of trade and ideas" for those who intended to set up their own businesses.

But his technical background alone does not explain the reason why just that machine was selected; the cultural environment he grew up in, should also be considered. |

|

|

| 1890-1900: a hard challenge

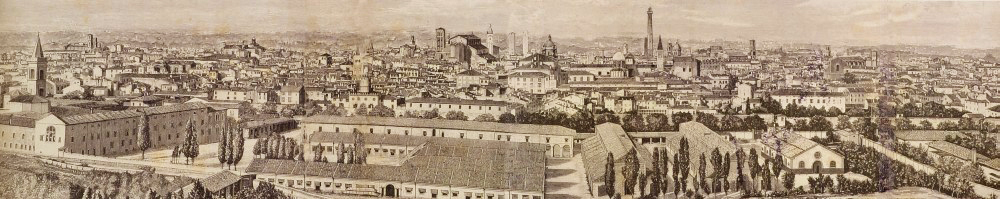

By the end of the century Bologna was a city of about 150,000 inhabitants and was undergoing an important industrial metamorphosis, influenced by the other European countries. It was at this time that experimentation with modernization began. The city could also count on its own reach and lively popular culture, which was boasting – among other things – many successful endeavours in the cooking and gastronomy fields. To notice it, it was enough to tour the shops around town, to sit in a cafe’, or to walk into a restaurant or a local trattoria.

Here the sfoglia (literally, "the dough-sheet") was a cult.

Everybody knew that women at home would get up early in the morning to start mixing tender wheat flour and eggs, then "draw the dough" with the rolling-pin to make tagliatelle and other fresh pasta.

For centuries during holidays, tortellini were the true king of the table, known all over the world for their small and curious shape, one that would even be compared to Venus' navel.

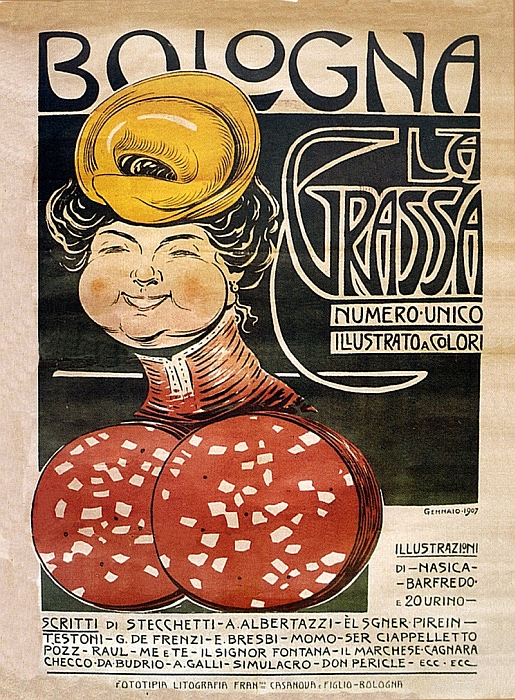

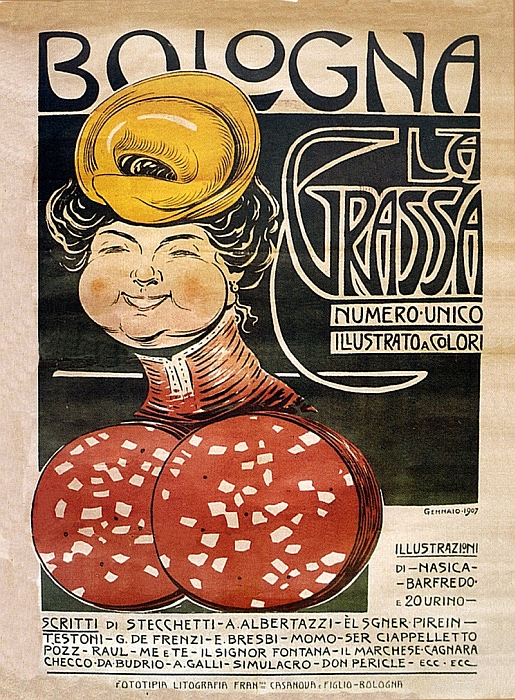

In a poster of the time, Bologna appeared as a well-off lady – "the fat one" - showing off her historic gastronomic qualities: two luxuriant mortadella breasts and a strange tortellino hat.

Trying to re-create this "myth" through a machine seemed impossible. |

|

| 1901- 1903: forms of industrial production .1

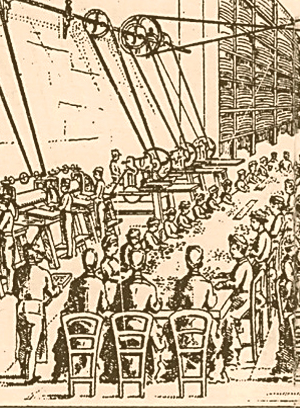

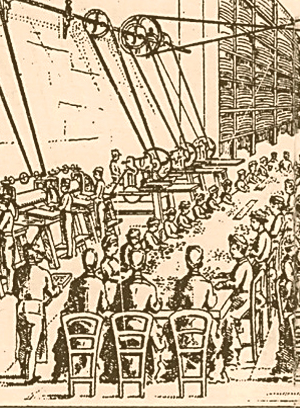

There were, however, various novelties that encouraged the enterprise. In Bologna, the factories producing pasta represented one of the fastest growing industrial sectors, as well as one of the most dynamic. An advertisement for a rapidly growing company of the time shows a picture of the factory’s production hall: on the left, the rows of kneaders and pasta sheet machines operated by male workers, and on the right, the 2HP steam engine, from which the transmission belts departed close to the grinding machine for the meat of the stuffing. In the centre you can see the "tortellinaie", as they called the women shaping the tortellini, sitting in front of a long table, while stuffing and "tightening" the pasta's edges incessantly to turn them into tortellini. This was a first production line "ante litteram". However, in the manufacturing the handiwork still prevailed. Zamboni instead was looking to create a machine to automate the tortellini making process.

|  |

1901- 1903: forms of industrial production .2

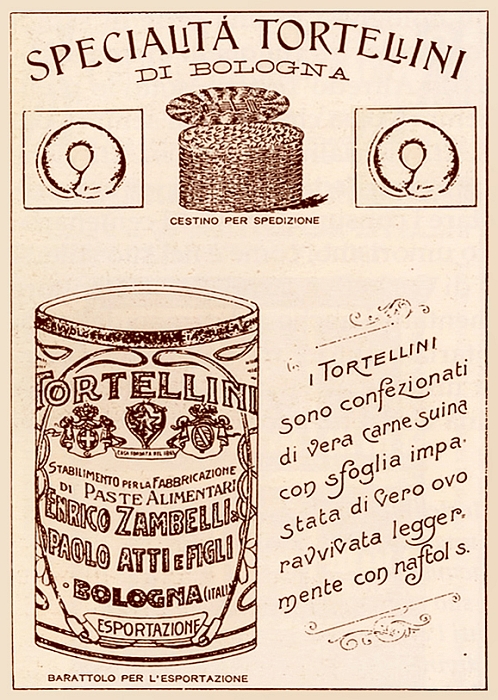

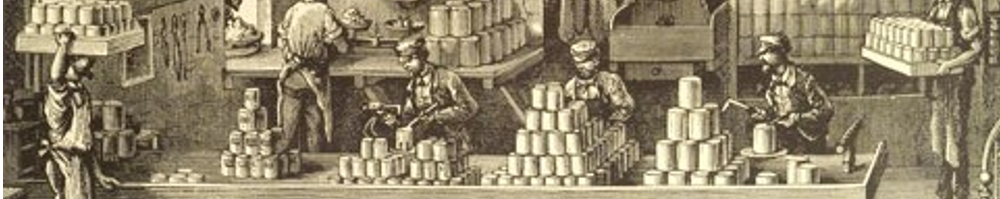

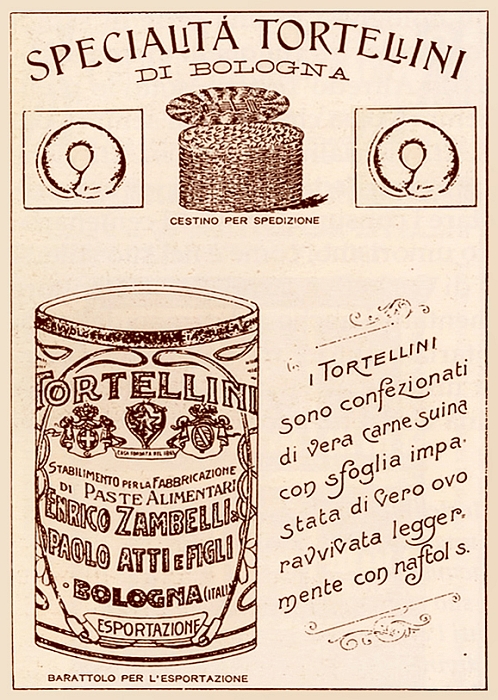

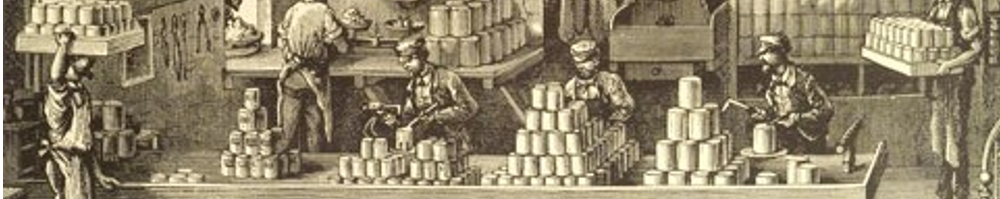

The same advertisement catalogue stated that for overseas export, following the example of mortadella, tortellini too had to be packed inside liquid-filled steel tins to prevent air from entering, thus guaranteeing one year preservation. For shorter distances, small cases, baskets, straw baskets, or even cardboard boxes were still preferred. Customers could buy 500 pieces for 4 Liras or 1000 pieces for 7 Liras. n the above described production line, the machines successfully contributed to the production of the famous egg-tagliolini (called "nun-style" for their quality) as well as other types of fresh, "home-made style" pasta.

|

|

|

1904-1906: a Company like ours was needed

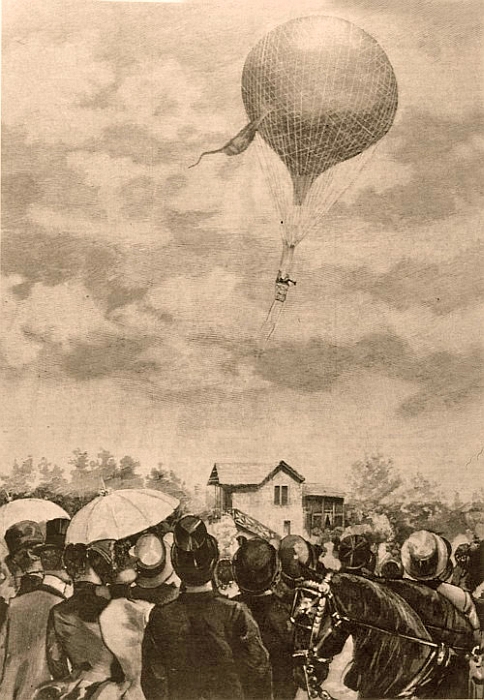

In 1904, Guglielmo Marconi was given the degree ad honorem in engineering by the University. In the town centre, at Middle Market street, the first cinema named "Marconi" was opened by simply displaying a great white cloth in the fish store. The same year, Luigi Zamboni started his own activity, with a small carpentry shop registered at the Chamber of Commerce. It was immediately evident that the enterprise needed different means, and the problem was solved in 1906, when Zamboni found a partner to his venture – 29 year-old Joseph Troncon. Troncon came from the city of Treviso in the Veneto region, and he was a mechanic too. Together, with 12,000 Liras of capital stock, they formed a society of general partnership, i.e. "ZAMBONI & TRONCON", with a workshop in downtown Bologna, at 19, Frassinago Street. Zamboni remained the majority partner of the company with a capital stock of 7,000 Liras. Maybe, that same year these two new partners celebrated the event, like many other bolognesi, by going to the Lawns of Caprara to see the America put on by Buffalo Bill's Company, who arrived to Europe to perform a show with more than 800 people, 500 horses and some authentic redskins. |

|

1907-1912: from the ideas to the machines

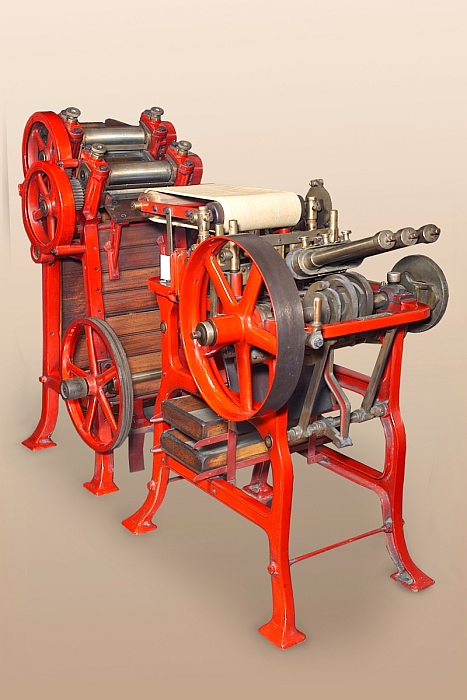

In the shop at Frassinago Street, between 1907 and 1911, they successfully designed and manufactured - in addition to tortellini machines - other original "special machines for pasta factories". The first tortellini machine, which is still owned by the company today, was able to produce 5000 pieces in an hour, which is equivalent to the work of more than 20 people. It consisted of a calibrating and of a shaping unit. The calibrating unit had rolls to reduce the dough-sheet to the correct thickness. The shaping unit cut the dough-sheet to small squares, delivered the right quantity of stuffing by means of pistons with counterweight, and then made the closing in the shape of tortellino. As the catalogues reported, the machine was quite "special" because of its automation, and it got national recognition in 1912 when it was appointed the gold medal for the "Umberto I° Prize".

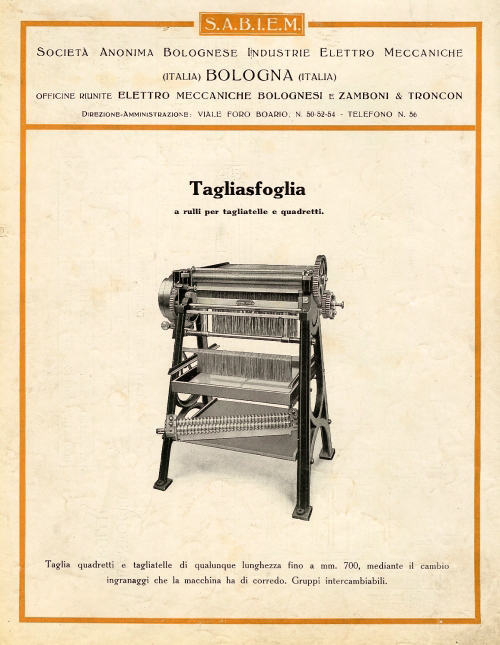

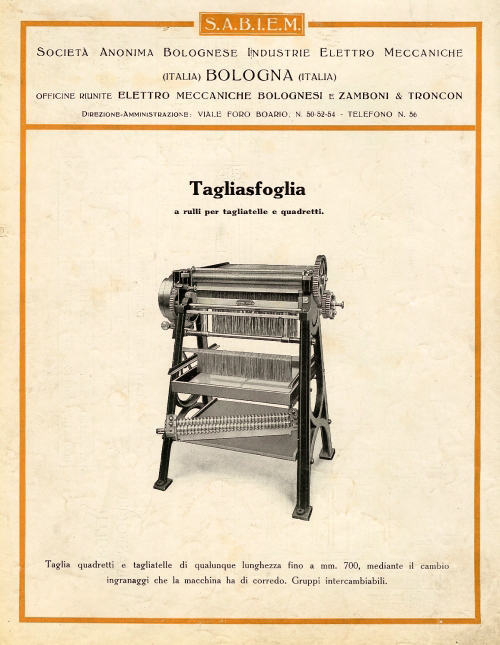

The other machines manufactured to produce fresh pasta were of no less value. The "Trinciatrice Piegatrice" (stamping/cutting machine) was sold to the greatest pasta factories in Italy and other foreign countries to produce new shapes and sizes of what was now called "Bologna-style pasta", such as stricchetti, paniere, farfalle,,farfalloni, lance, palette, margherite, cornetti smeraldo, also in different sizes. When hand-made, these shapes required heavy costs for manual labour; now, one single machine was able to produce 250-500 Kg of pasta on a daily basis. The "Dough-sheet cutter" produced tagliatelle and quadretti ("small squares") by simply replacing the knife with changeable toothed rolls that allowed different lengths. The "Machine to fill packets of pastine glutinate", (tiny pieces of pasta with gluten, suitable for soups) represented some of the first packaging solutions, by saving manpower while guaranteeing perfect precision in the dimensions of packets from 150 to 300 grams. These machines had a market in Italy, Austria, Principality of Monaco, Germany, France, Greece and Latin America. |

|

1913-1918: a leading Company in Bologna's district |

The 1915 picture representing the employees of "ZAMBONI & TRONCON" shows about seventy people, many of which were young people, all with similar faces, expressions, and work attires. Even the "bow-tie" Zamboni used to wear on his black uniform doesn't clash with the common shop culture that the image conveys. But the picture tells us much more. Many of the youngest people attended or came from Santa Lucia technical school at 39, Castiglione Street. Here, the so called Institute of Arts and Crafts "Aldini-Valeriani" was training the town’s best mechanical engineers. In fact, our picture includes many people that would someday be famous:

| Armando Simoni, founder of the "OMAS" for the production of fountain-pens; |

| Otello Cattabriga owner of a new firm for the production of ice-cream machine; |

| the young Paolo Zuccoli, who will have the opportunity of specializing the use of the mechanical dies in the pasta machines; |

| |

| Antonio Zamboni, the 24 year-old son of Luigi, |

| and a young apprentice, Bruno Mazzanti, 15 years old, who will give continuity to the history of "ZAMBONI". |

They are some of the many technicians who will be active in Bologna between the twenties and the second post-war period; those same technicians who will be laying the foundations for the city’s present industrial district of small and medium engineering companies in the field of electro-mechanics and automation, able to compete on the great international market. |

|

1919-1924: Company's ups and downs

But in 1919 the Society disbanded. It is said that Zamboni went to produce to Marseille, in France, with a new factory of his own. Troncon continued the activity alone, maintaining unchanged the name of the firm until 1921, when he involved the company in an intricate financial operation that, with the involvement of other companies, lead to the establishment of "Sabiem", "Società Anonima Bolognese Industrie Elettromeccaniche" (Bolognese Corporation of the Electro-Mechanic Industries). The Society’s objective was to promote diverse production and Troncon became the company’s technical manager. In January 1924, when the Society decided to close the shop at Frassinago street, Zamboni was ready to take back his activity with the name of "Luigi Zamboni", and with the proud addition of "construction of machines for the production of stuffed tortellini". This is an interesting chapter in the history of our Company and in general too, because it confirms how the roots of a productive activity represent a strong patrimony for the continuing growth and development of the same company. |

|

1925-1945: tradition continues |

In 1930 Zamboni's son Antonio together with two partners, Bruno Mazzanti and Aldo Marchesi, both technicians inside the firm, took over the management of "Officine Meccaniche Zamboni", with a capital stock of 100,000 Liras (1/3 each) and 20 employees. Luigi Zamboni died shortly afterwards, on March 9, 1932, in a Bologna with 250,000 inhabitants that didn’t look as promising as it had in previous years. 1931 saw the inauguration of the cableway up to the hill of San Luca, a project that dated back to the late 19th century. In May 1932, less than a year later, an enthusiastic public gathered in San Michele in Bosco to admire a parade of 800 airplanes following a simulated bombardment over the town. The economic data published by the Chamber of Commerce was alarming, and the pasta industry experienced difficulties due to the impossibility for Italy to export to some foreign markets where the machines for "Bologna-style pasta" had important buyers. During the troublesome transition of the war and post-war period, Bruno Mazzanti successfully drove the firm toward new and important Zamboni machines. |

Zamboni in via Frassinago |

1946-1954: the post-war period |

|

In the immediate post-war period, while the modern industrial transformation of the town consolidated, the "Officine Meccaniche Zamboni" were still located in the historical seat of Frassinago street. Not until 1954 were the shops transferred to Bologna, at Cimabue street. These were the years of the reconstruction, when the district of the small and medium local companies was growing up, producing innovative technologies in motorcycles, in automatic machines and in machines for packaging, dosing, packing the products, with patents and solutions that are part of the machine history.

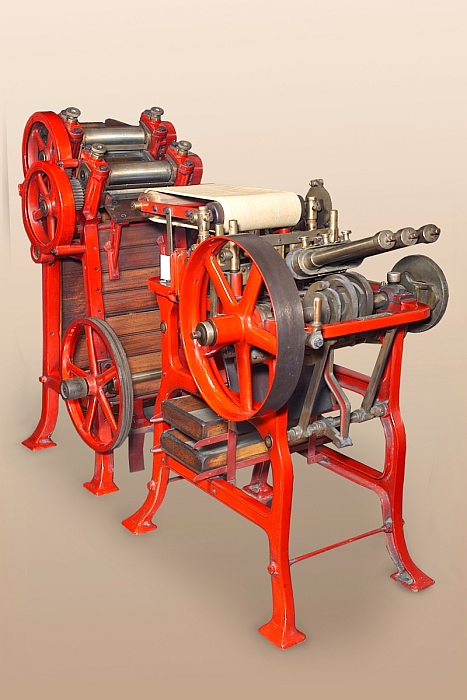

The machines showed in the picture belong to those years. They originated from the bakery at Dei Neri street in Florence. The owner Anna Zangheri, last descendant of several generations of bakers, stopped her activity in 1999 and delivered her machines to the Museum of Bologna's Industrial Heritage. Our Company, heir of Zamboni's tradition, has recovered and restored them in collaboration with the Museum that still has them on exhibit. At Christmas these machines produced up to 1000-1500 kg/daily of tortellini and ravioli, which were then packed in great baskets of different capacities and home delivered by hand. After the use the machines were partly disassembled, washed and then reassembled. In 1966 these machines suffered the Florence great flood, remaining submerged under water. Afterwards, at record time, the "Officine Meccaniche Zamboni" and their technicians in Bologna succeeded in putting them again into production in as soon as 20 days. |

Zamboni in via Cimabue |

1955-2010: in the district around us |

On November 23, 1955 Bruno Mazzanti suddenly died at just 55 years of age, leaving his responsibilities to his young children, 25 years-old Gianna and 20-years-old Antonio. It will be Gianna's husband, 30 year-old engineer Federico Bugo to lead the Company into the new millennium. In 1964 he will also move the factory to Casalecchio di Reno. |

Zamboni in via Verga |

When he died, on June 12, 2005, the management passed to another engineer, his son Andrea, who is continuing the tradition with the same historical name of "Officine Meccaniche Zamboni" in the new seat at Casalecchio di Reno, 73 Cimarosa street. |

Zamboni in via Cimarosa |

Saluto di Olindo Guerrini |

| To greet them all, we address them as the "good housekeepers", as per Olindo Guerrini, in art Lawrence Stecchetti, satirical poet and gourmet from the turn of the century, that is, at the time when everything started: |

Fate una pasta d'ova e di farina /

e riducete rimenando il tutto /

in una sfoglia, ma non troppo fina /

uguale, soda e, sul taglier pulito, /

fatene tagliatelle larghe un dito /

che faremo bollire allegramente /

in molta acqua salata, avendo cura /

che, come si suol dir, restino al dente

(make a dough with eggs and flour / and by mixing the whole reduce it / in a dough-sheet, but not too thin / even, firm, and on the clean cutting board / cut one finger wide tagliatelle / that we will bring to happily boil / in a lot of salty water, by taking care / that, as it is usually said, they remain underdone)

|

Consulted sources:

- Photographic and documents files of "Officine Meccaniche Zamboni"

- Museum of Bologna's Industrial Heritage, Fund of File "Zamboni"

- Museum of Bologna's Industrial Heritage, Fund of File Paolo Zuccoli

- G. Maioli and G. Roversi, His Majesty the Tortellino, Bologna, 1993

- "SCUOLAOFFICINA" (school-shop), 1999, n.2, Roberto Curti, Machine Tortellini, pages 4-8

- Bologna's Comune, Made at Bologna, edited by Anthony Campigotto, Roberto Curti, Maura Grandi, Alberto Guenzi, Renografica Editions, Bologna 2000, pages 80-87

- Bologna's History, edited by Anthony Ferri and Giancarlo Roversi, Bononia Universitary Press, Bologna 2005

Company's biography written by prof. Roberto Curti, inventor in the eighties and then, from 1987 to 2003, responsible of the direction of Bologna's Museum of the Industrial Heritage.

Rino Bertuzzi has supported the text for the photographic part.

Special thanks to Dr. Maura Grandi and to the management of Bologna's Museum of the Industrial heritage for the received collaboration.

|

|

|