|

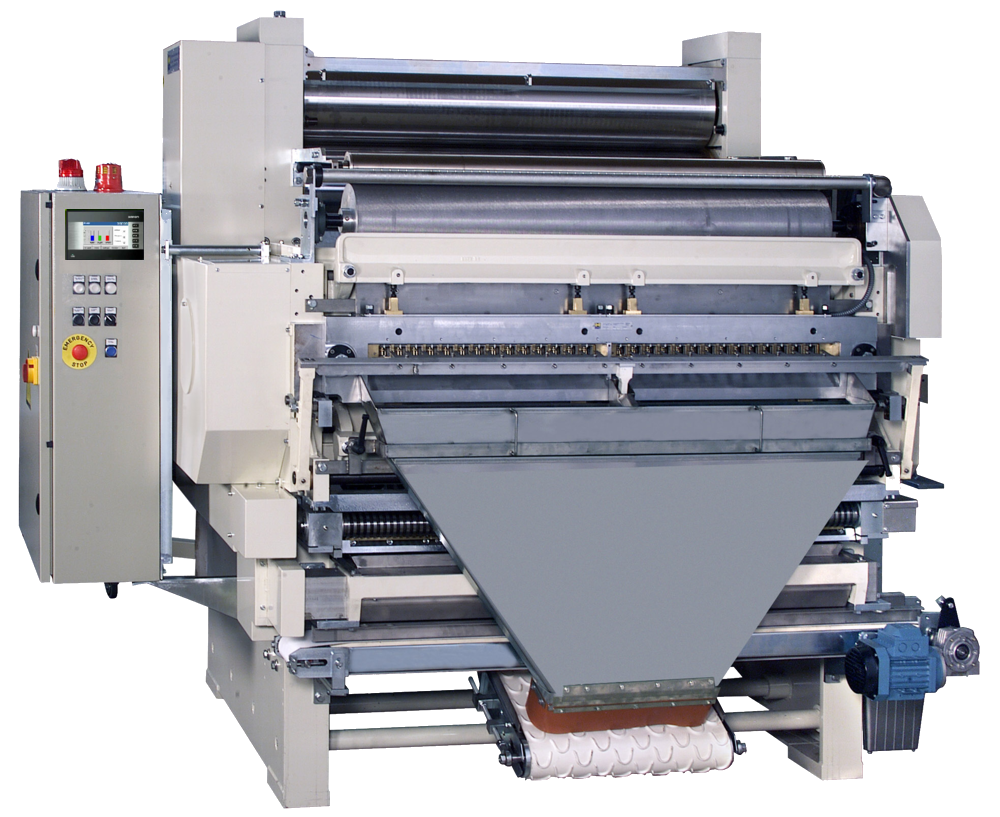

Stamping machine Velo/1200

The Stamping machine Velo/1200 for the manufacture of stamped pasta "Bologna-style" from a 1200 mm wide dough-sheet is born with following leading features:

Advanced mechanical technology which allows - together with its traditional sturdy structure - a 24-hour operation during many years; all that in absence of vibrations thanks to the perfect dynamic balance of all moving parts.

High manufacturing capacity granting, for example, an output up to 750 kg/h of dry "Farfalle 65/B" and 900 kg/h of "orecchiette".

Small overall dimensions as well as pre-arrangement for operation in connection with two or four stamping machines, so that it is possible to realize installations at the service of high performing presses even in relatively small rooms.

Supervision of correct operation through PLC.

A still more powerful calibration unit with manual or - as an option - through Encoder controlled adjustment of thickness to be saved in recipes in the PLC of the stamping machine or directly in the central PC of the production line together with other production parameters.

Elastic control system for finger unit of shape, with four upper and four lower thrust points, to achieve a perfect closing of the shape "farfalle" throughout whole width of mould - said unit equipped with mechanic security system, which has been calibrated at its maximum predetermined load so as to prevent the Stamping machine from possible overloads caused, for example, by wrong adjustments.

Cutting device for scraps, synchronized with dough-sheet movement, for longitudinal cutting and, optionally, for additional transversal cutting in order to further reduce dimension of scraps before their re-kneading, thus improving homogeneity between the new mixture and the scraps.

This machine is always delivered complete with pre-arrangement for:

Three-rollers lamination unit for the production of grooved shapes (Velo/1200 DL).

Dough-sheet thickness control through encoder, which allows the setting and recalling of 30 shapes and relevant parameters such as: thickness of dough-sheet, speed of lamination unit, speed of stamping station, and so on.

Installation of RW/1200 "squares" and "noodles" units.

A range of shapes more and more extensive allows to enrich the production with new designs.

|