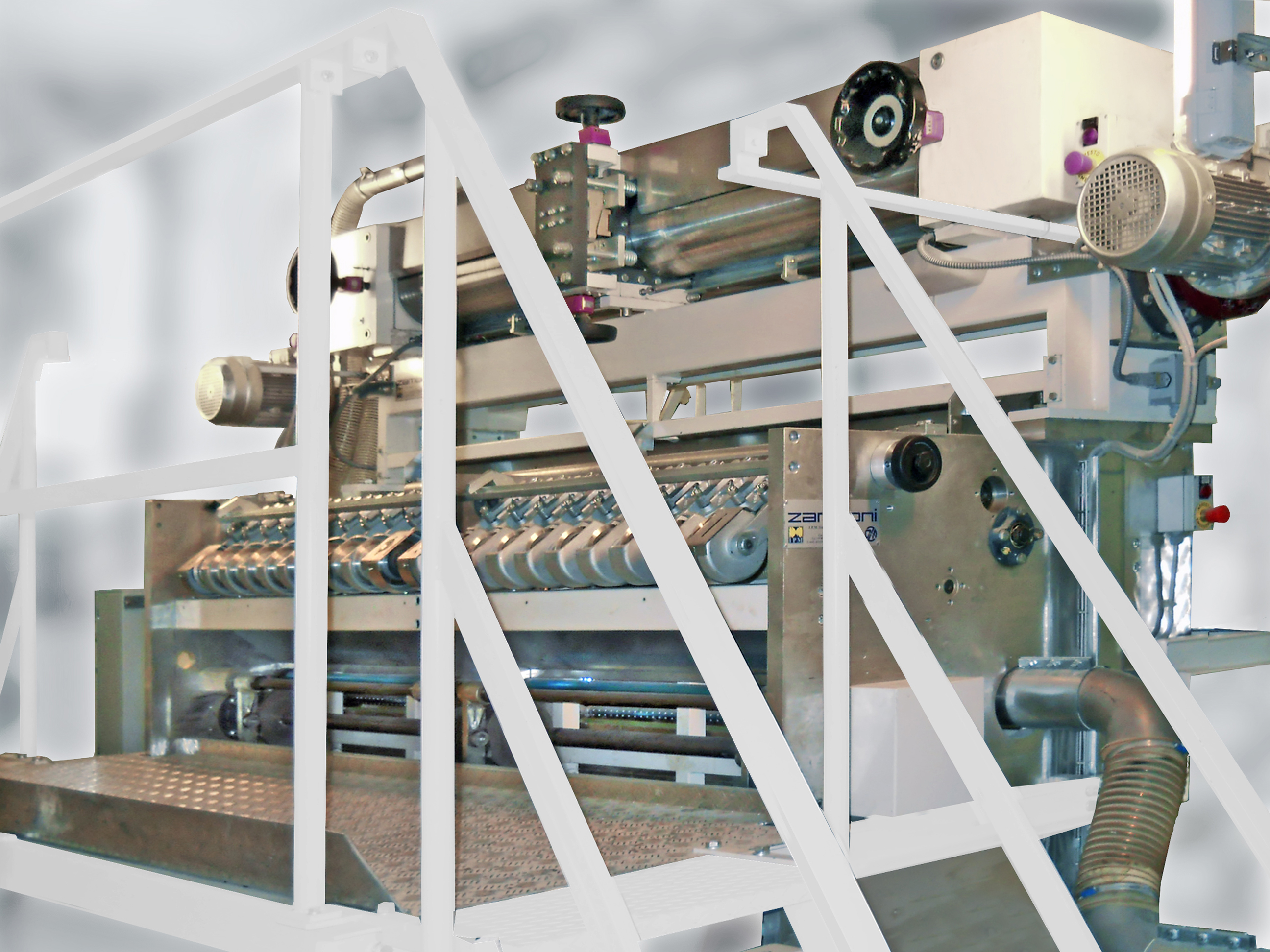

Lasagne Machine ML/2000

The machine for the production of lasagne: in the beginning it was a "device for Lasagne" (series AL/...) or a machine that had no "right" to its independent motorization and was placed at the service of nesting or coiling machines. It worked at a maximum speed equal to that of the nesting machines, i.e. a speed well below its real potential.

In the ML /... series the lasagne making device is finally equipped with an autonomous motorization and therefore becomes a machine to all the effects, but the automatic lines of drying are not yet ready to receive the production of the ML/... then again its speed is lowered by half compared to its potential.

Who first realize the potential of the lasagna and the market for this product are the small pasta factories that, not depending on the rhythms dictated by an automatic drier, install our ML/600 and use them at full speed, that is at 9 trays per minute.

We had to wait until 2005 to have a continuous drier capable of receiving 2000mm wide trays at 9 trays per minute: ML/2000 was there waiting for them!

The lasagne machine is composed of:

Calibration with twin motors.

Longitudinal cutting group, mechanically adjustable, to form lasagne of different width without replacing mechanical parts.

Cross cut assembly with programmed length via Touch Screen.

Advancement of trays, that takes charge of the tray from the return of the line, raises it through a suitable elevator and moves it under the lasagne machine with brushless motor and precision of a millimeter.

As an optional it is possible to mount the trim side group and its pneumatic return of the scraps to the press.

|

![]()

![]()