|

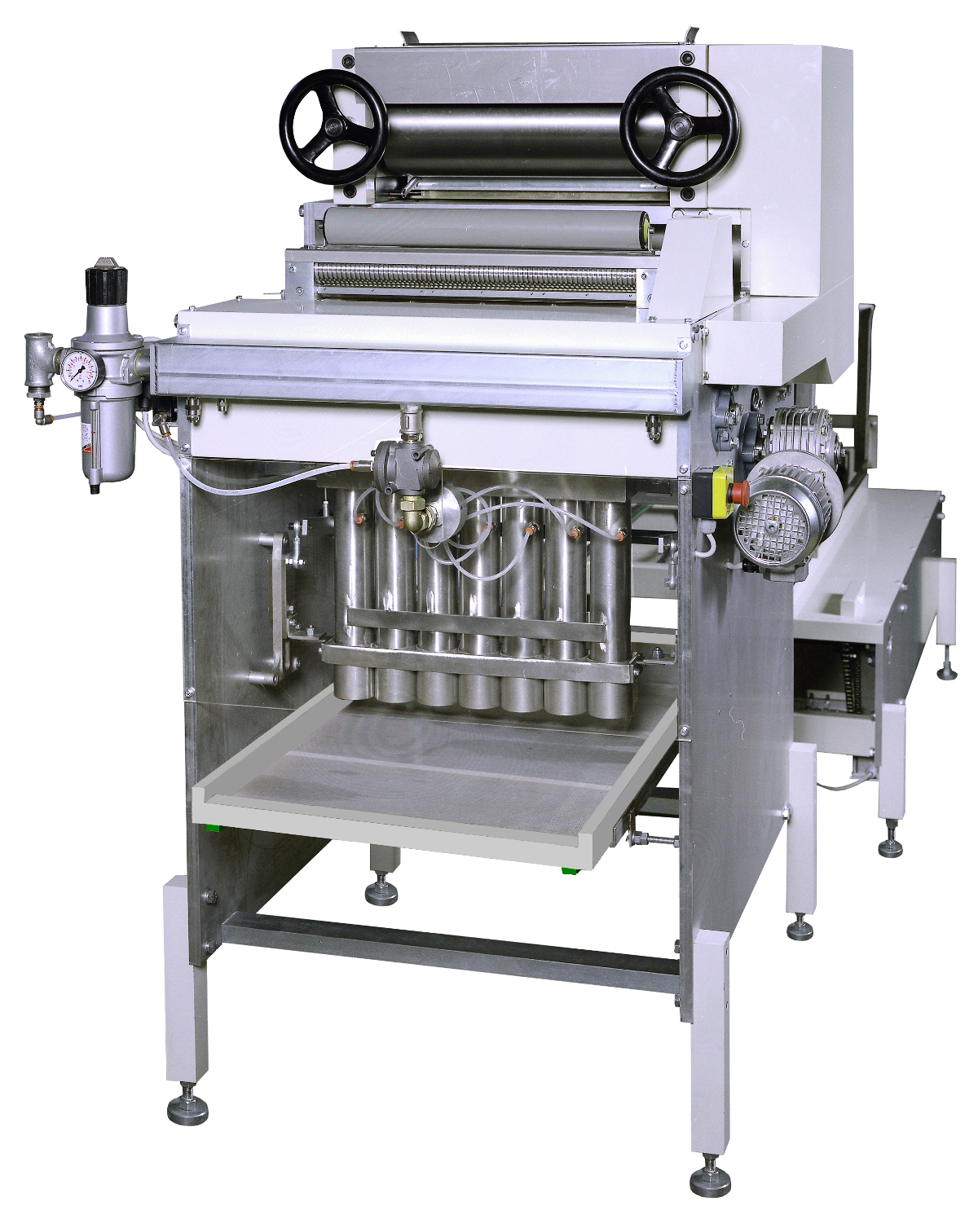

Nest-forming machine NLA/600

Autonomous Machine for the manufacture of nests from a dough-sheet (coming out from a press or a kneader) or from a drawn, normally equipped with:

Calibrating unit with autonomous motorization, suitable to receive a 510 mm wide dough-sheet and reduce it to the requested thickness.

Unit for transversal cut of noodles or dough threads by means of a special device allowing the passing of threads with arrested knives and the cutting through a fast rotation of the blades. To rectify the nest weight, it is possible to vary, with operating Machine, the cutting length of noodles or drawn threads.

Nest-forming made inside special cups by means of compressed air jet, under PLC control of the Machine. A telescopic unit allows to approach the net during the forming phase and to move away during the phase of tray translation.

Advancement of 600 mm wide trays through autonomous motorization under PLC control, with advancement steps which are programmable according to the nest-shape, in order to quickly shift - for example - from the production of a round nest to an oval one.

Machine pre-arranged to be equipped, according to the production needs, with:

different couples of cutting roller to effect, in synchronization with the calibration, the longitudinal cuts of the dough-sheets, cuts of the type:

Parallel, according to any requested width.

Undulated, to simulate the manual cut.

Differentiated, to obtain different noodle widths inside the same nest, thus maintaining the same final weight of the various nests.

Spur-shaped  , to get an indentation in the cutting profile. , to get an indentation in the cutting profile.

Troccolo Pugliese  . .

set of special cups to form round or oval or flat nests.

side trimming of dough-sheet, with relevant scraps mincing and return to the press.

special support of tray during nest deposition phase, such as even very worn trays or with buckled net can be used.

trays lift for connection with automatic drying lines.

equipment for the production of lasagne (AL/600), moved through the motorization of the Nest-forming machine.

|